In 2021, we launched our carbon footprint project. Our schoolbags have been made from recycled polyester for the past 5 years, but we wanted to understand our environmental impact to find out how we could further improve.

To do this, we enlisted the help of a specialist: La Belle Empreinte , which helps companies to set an example in terms of eco-responsibility. The process took place in 3 stages:

1. Measuring our carbon impact.

2. Complete impact measurement.

3. diagnosis and eco-design.

We worked with them to analyze the life cycle of all our products, using the French ADEME and European PEF methods. This method also enables us to evaluate ourselves against the market average, which is an indicator for our buyers looking for more responsible products.

A product's life cycle represents its journey from conception to end-of-life. Each stage is carefully analyzed: we assess the environmental impact of materials production, manufacturing, daily use by children, and even the product's end-of-life. This enables us to make informed decisions to minimize our carbon footprint at every stage, without compromising style or quality. Our entire production chain took part in this exercise: material suppliers, spare parts manufacturers, manufacturing workshops, logisticians, transporters... and our entire team.

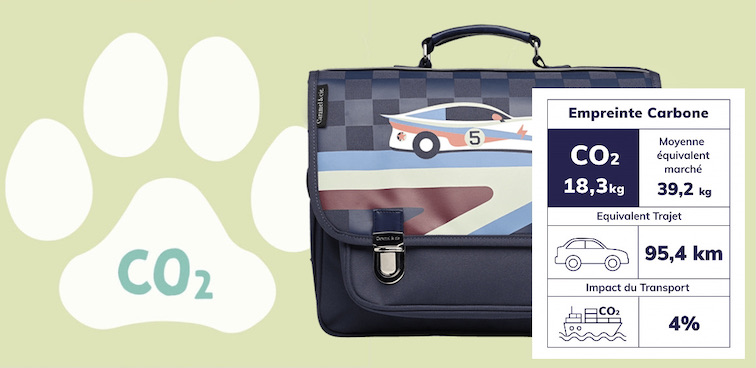

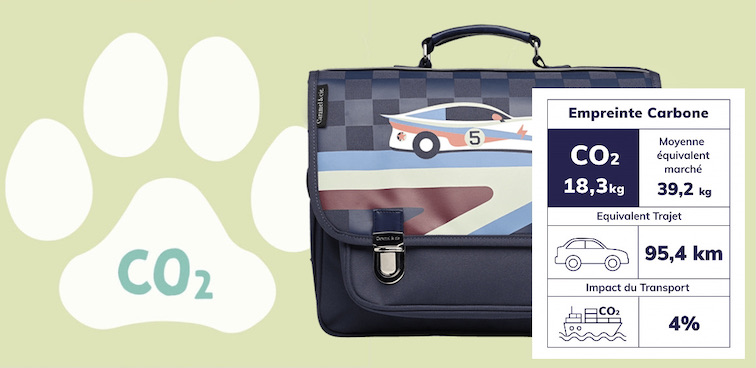

We reveal our carbon footprint analysis

We have drawn some interesting and sometimes surprising conclusions from this:

- 80 to 90% of the carbon footprint of our products (the difference depends on the type of product) is generated by the material and finishing (printing, embroidery, etc.);

- Our products have a carbon footprint that is nearly 40% lower for schoolbags and 35% lower for backpacks than the market average;

- La Belle empreinte determined the carbon footprint of the "ideal schoolbag" and compared it to our products. Our performance ranged from 75% "good" (blue butterfly duffel bag) to 93% "ideal". (Medium Rainbow Star schoolbag). We're pretty proud of these figures!

- transport represents only 2% to 4% of our products' carbon footprint. A relocation of manufacturing would therefore have no impact on our carbon footprint - quite the contrary, in fact, since we take care to ensure that all our materials and accessories are sourced very locally around our manufacturing workshops, which would be impossible to find in Europe (at least we haven't found one yet!).br />

- As we analyzed in a previous article « Recycled polyester: an eco-responsible solution? », even if it seems counter-intuitive, recycled polyester remains the best choice for optimizing our eco-responsibility, even when compared to other materials such as organic cotton (it takes 5 tons of water to produce 1kg of cotton) or Lyocell (fiber derived from wood pulp).

Conquering eco-design

Back in 2022, we embarked on an eco-design approach for our products. We recruited William, who is a product designer, and entrusted him with this mission. Fabienne, our production manager, piloted the project with La Belle Empreinte and pushed our suppliers and workshops to optimize our production process by integrating these eco-design constraints.

For the new 2023 collection, designed in 2022, we use mainly recycled polyester for the manufacture of our schoolbags, representing 80% of their composition. Unfortunately, we had relatively little room for improvement, since materials and printing account for 80% of our carbon footprint, and the patterns and graphics on our schoolbags are the very DNA of our brand.

We've started to look at ways of reducing the amount of fabric used, as well as the elements that make recycling difficult or impossible. All fabrics and yarns used in our schoolbags are GRS-compliant recycled polyester.

However, for certain elements such as the bottom, certain tabs and bias, we use imitation leather because of its appearance and resistance to wear and tear (our kids are real schoolbag torturers!). Unfortunately, these materials cannot be recycled due to their polyurethane coating.

We're constantly evolving, and soon we'll be offering collections made entirely from 100% recycled materials. And for the next collection, we've revised some designs to reduce the amount of fabric used.

Our ultimate goal is to achieve an all-recycled polyester composition for our schoolbags to facilitate their recycling. Currently, the high cost of recycling is due to the dismantling process, which takes almost as long as the actual manufacture of a schoolbag! That's why every year we reinforce our schoolbags to make them last longer. We know we'll sell fewer of them as a result (some of our schoolbags last more than 5 years!), but we're doing it with our children in mind!

Now you know all about our efforts to bring you schoolbags that are better, or rather less harmful (let's not mince words!) to the planet. We'll keep you posted on our progress.

Happy vacations to you all, and don't forget: use sunscreens that respect the oceans and coral reefs!

Published the 07/03/2023

We've calculated the carbon footprint of your schoolbag!

- 80 to 90% of the carbon footprint of our products (the difference depends on the type of product) is generated by the material and finishing (printing, embroidery, etc.);

- Our products have a carbon footprint that is nearly 40% lower for schoolbags and 35% lower for backpacks than the market average;

- La Belle empreinte determined the carbon footprint of the "ideal schoolbag" and compared it to our products. Our performance ranged from 75% "good" (blue butterfly duffel bag) to 93% "ideal". (Medium Rainbow Star schoolbag). We're pretty proud of these figures!

- transport represents only 2% to 4% of our products' carbon footprint. A relocation of manufacturing would therefore have no impact on our carbon footprint - quite the contrary, in fact, since we take care to ensure that all our materials and accessories are sourced very locally around our manufacturing workshops, which would be impossible to find in Europe (at least we haven't found one yet!).br />

- As we analyzed in a previous article « Recycled polyester: an eco-responsible solution? », even if it seems counter-intuitive, recycled polyester remains the best choice for optimizing our eco-responsibility, even when compared to other materials such as organic cotton (it takes 5 tons of water to produce 1kg of cotton) or Lyocell (fiber derived from wood pulp).

In 2021, we launched our carbon footprint project. Our schoolbags have been made from recycled polyester for the past 5 years, but we wanted to understand our environmental impact to find out how we could further improve.

To do this, we enlisted the help of a specialist: La Belle Empreinte , which helps companies to set an example in terms of eco-responsibility. The process took place in 3 stages:

1. Measuring our carbon impact.

2. Complete impact measurement.

3. diagnosis and eco-design.

We worked with them to analyze the life cycle of all our products, using the French ADEME and European PEF methods. This method also enables us to evaluate ourselves against the market average, which is an indicator for our buyers looking for more responsible products.

A product's life cycle represents its journey from conception to end-of-life. Each stage is carefully analyzed: we assess the environmental impact of materials production, manufacturing, daily use by children, and even the product's end-of-life. This enables us to make informed decisions to minimize our carbon footprint at every stage, without compromising style or quality. Our entire production chain took part in this exercise: material suppliers, spare parts manufacturers, manufacturing workshops, logisticians, transporters... and our entire team.

We reveal our carbon footprint analysis

We have drawn some interesting and sometimes surprising conclusions from this:

Conquering eco-design

Back in 2022, we embarked on an eco-design approach for our products. We recruited William, who is a product designer, and entrusted him with this mission. Fabienne, our production manager, piloted the project with La Belle Empreinte and pushed our suppliers and workshops to optimize our production process by integrating these eco-design constraints.

For the new 2023 collection, designed in 2022, we use mainly recycled polyester for the manufacture of our schoolbags, representing 80% of their composition. Unfortunately, we had relatively little room for improvement, since materials and printing account for 80% of our carbon footprint, and the patterns and graphics on our schoolbags are the very DNA of our brand.

We've started to look at ways of reducing the amount of fabric used, as well as the elements that make recycling difficult or impossible. All fabrics and yarns used in our schoolbags are GRS-compliant recycled polyester.

However, for certain elements such as the bottom, certain tabs and bias, we use imitation leather because of its appearance and resistance to wear and tear (our kids are real schoolbag torturers!). Unfortunately, these materials cannot be recycled due to their polyurethane coating.

We're constantly evolving, and soon we'll be offering collections made entirely from 100% recycled materials. And for the next collection, we've revised some designs to reduce the amount of fabric used.

Our ultimate goal is to achieve an all-recycled polyester composition for our schoolbags to facilitate their recycling. Currently, the high cost of recycling is due to the dismantling process, which takes almost as long as the actual manufacture of a schoolbag! That's why every year we reinforce our schoolbags to make them last longer. We know we'll sell fewer of them as a result (some of our schoolbags last more than 5 years!), but we're doing it with our children in mind!

Now you know all about our efforts to bring you schoolbags that are better, or rather less harmful (let's not mince words!) to the planet. We'll keep you posted on our progress.

Happy vacations to you all, and don't forget: use sunscreens that respect the oceans and coral reefs!